Electrical Tensioners for Optimal Coil Winding Control

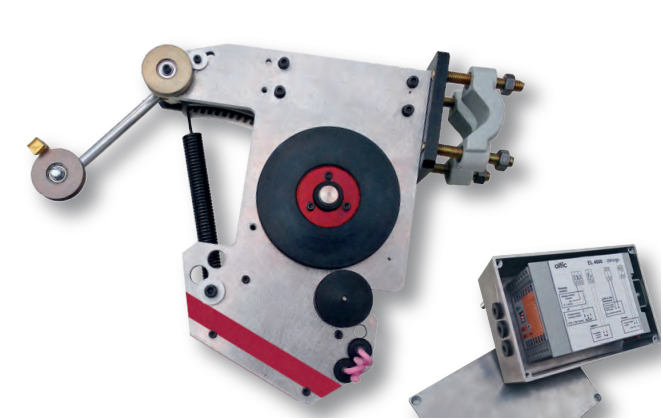

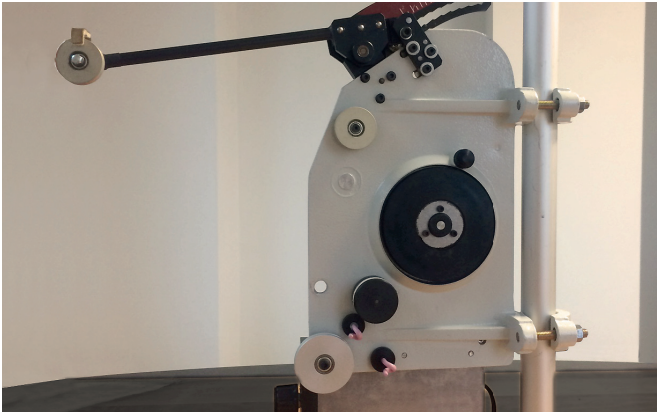

The use of electrical tensioners in coil winding processes is crucial for maintaining consistent wire tension, ultimately leading to higher quality and precision of the final product. These tensioners come in various types, including mechanical, electronic, and magnetic, offering different levels of control and adaptability for various winding operations. They also provide features such as precision control, adaptability to different wire sizes and materials, reduced maintenance, and enhanced productivity. Common applications for electrical tensioners include transformer manufacturing, motor production, and speaker manufacturing. Choosing the right tensioner depends on factors such as wire specifications, winding speed, and specific application requirements. ALTIC’s Electric Tensioners, equipped with EMP Brake technology, offer a cost-effective solution for upgrading existing coil winding machines with remote control capabilities. With oversized EMP brakes, these tensioners provide high performance and a longer service life. The EL4000, GR64 E4, and GR64 E10 are some of the options available in the product range.

Types of Electrical Tensioners

When it comes to the winding industry, the utilization of electrical tensioners in the coil winding process is undeniably crucial. These sophisticated devices are specially designed to maintain the optimal tension of the wire, thereby ensuring the production of high-quality, consistent coils. The diverse range of electrical tensioners available caters to the specific needs and requirements of various winding processes.

Among the different types of electrical tensioners, mechanical, electronic, and magnetic tensioners are the most prominent and widely employed in the industry. Each of these distinct tensioner types offers unique features and advantages, making them suitable for different coil winding applications and environments.

By incorporating advanced technology and innovative features, mechanical, electronic, and magnetic tensioners play a pivotal role in enhancing the efficiency, precision, and overall quality of the coil winding process. This in-depth overview will explore the diverse types of electrical tensioners and their individual characteristics, providing valuable insights for selecting the most suitable tensioner for a specific winding application.

Mechanical Tensioners

Mechanical tensioners have been a staple in the industry for many years due to their straightforward design and reliable performance. These tensioners utilize friction to modulate the wire tension, making them a simple and cost-effective choice for various coil winding applications. The robust construction and ease of use of mechanical tensioners make them a popular option for manual winding processes and low-speed applications.

While mechanical tensioners may not offer the advanced control features found in electronic or magnetic tensioners, their reliability and straightforward operation make them a go-to solution in specific winding scenarios. For manufacturers seeking a dependable and cost-efficient tensioning solution for less demanding winding processes, mechanical tensioners prove to be an ideal choice.

Electronic Tensioners

Equipped with advanced control systems, electronic tensioners represent a significant advancement in the field of coil winding technology. These sophisticated devices offer precise and adjustable tension management, making them highly suitable for high-speed and high-precision winding operations. The real-time tension adjustments possible with electronic tensioners enable manufacturers to maintain consistent wire tension, thereby ensuring the production of uniform and high-quality coils.

The versatility of electronic tensioners allows them to be seamlessly integrated into automated winding systems, further enhancing their functionality and efficiency. By providing advanced control and monitoring capabilities, electronic tensioners contribute to the optimization and automation of the winding process, ultimately leading to improved productivity and product consistency.

Itasca Electrical Tensioner Models

Features and Benefits of Electrical Tensioners

Electrical tensioners offer a wide array of features and benefits that are integral to the optimization and quality assurance of the coil winding process. From precision control to reduced maintenance and enhanced productivity, the advantages of using electrical tensioners are far-reaching and impactful across various industries and applications.

The adoption of electrical tensioners in coil winding operations brings forth a multitude of benefits that contribute to the overall performance and output quality of the winding process. These benefits, including precision control, adaptability, reduced maintenance, and enhanced productivity, underscore the pivotal role of electrical tensioners in ensuring consistent and superior coil production.

Precision Control

One of the primary features and benefits of electrical tensioners is their capability to deliver precise control over wire tension during the winding process. This level of precision is crucial for producing coils with uniform and consistent characteristics, such as inductance resistance and capacitance. By maintaining exact tension settings throughout the winding process, electrical tensioners play a significant role in ensuring the quality and reliability of the final product.

Whether in high-speed, automated applications or manual winding processes, the precision control offered by electrical tensioners is instrumental in guaranteeing the optimal and uniform winding of wire coils, thereby meeting the stringent quality standards required in various industries, including transformer manufacturing, motor production, and speaker manufacturing.

Adaptability

The adaptability of electrical tensioners further underscores their value in a diverse range of winding applications. Many electrical tensioners are designed to handle a wide range of wire sizes and materials, making them versatile and suitable for various winding operations. This adaptability enables manufacturers to utilize the same tensioner for different coil designs, providing a cost-effective and efficient solution for managing diverse winding requirements.

By accommodating different wire types and sizes, electrical tensioners contribute to streamlining the winding process and minimizing the need for frequent reconfiguration, thereby promoting operational efficiency and flexibility in manufacturing environments where a diverse range of wire coils are produced.

Reduced Maintenance

Advanced designs, such as those featuring magnetic resistance, play a key role in minimizing mechanical contact and wear, leading to reduced maintenance requirements for the tensioners. This reduction in maintenance not only extends the service life of the tensioners but also contributes to enhanced reliability and operational efficiency in the long term.

Furthermore, the streamlined maintenance needs of electrical tensioners, especially magnetic tensioners, translate to lower downtime and maintenance costs, providing a comprehensive and sustainable solution for manufacturers seeking reliable and low-maintenance options for their coil winding processes.

The benefits of reduced maintenance and prolonged service life further solidify the case for integrating advanced electrical tensioners into the production line, as these advantages contribute to improved overall productivity, reduced operational costs, and consistent output quality, thereby representing a strategic and value-oriented investment in winding technology.

Enhanced Productivity

By maintaining consistent and optimal wire tension, electrical tensioners play a pivotal role in enhancing the overall productivity of the winding process. The minimization of wire breakage and defects, as well as the optimization of the winding process, directly contribute to smoother operations and higher throughput, thereby driving the overall productivity of the manufacturing process.

With the implementation of electrical tensioners, manufacturers can experience a significant reduction in rework, scrap, and production delays, ultimately leading to improved efficiency and cost-effectiveness in their coil production operations. The augmented productivity facilitated by electrical tensioners not only meets the increasing demands for high-volume and high-quality production but also elevates the competitive advantage of manufacturers in the market by ensuring the timely and seamless delivery of superior coils.

Applications of Electrical Tensioners in Coil Winding

The versatile and indispensable nature of electrical tensioners finds applications in a broad spectrum of industries, where the reliable and precision-driven control of wire tension is a fundamental requirement. From transformer manufacturing to motor production and speaker manufacturing, electrical tensioners are instrumental in ensuring the production of high-quality and precisely wound coils that meet the demanding standards of various applications.

Specifically, the applications of electrical tensioners extend across different sectors, each with its unique winding requirements and quality imperatives. By exploring the diverse applications of electrical tensioners, manufacturers can gain valuable insights into the industry-specific benefits and considerations that underpin the selection and utilization of electrical tensioners in their winding operations.

Transformer Manufacturing

In the realm of transformer manufacturing, the role of electrical tensioners in ensuring uniform tension in transformer coils is pivotal for optimizing the performance and longevity of the transformers. The precise control and consistency provided by electrical tensioners are critical in producing transformer coils with the exact inductance and resistance characteristics necessary for the efficient operation of electrical transformers.

By integrating electrical tensioners into the production process, transformer manufacturers can achieve a new level of quality assurance and process optimization, thereby delivering transformers with enhanced performance, reliability, and longevity in response to the stringent requirements of electrical power systems and applications.

Motor Production

Likewise, in the domain of motor production, the implementation of electrical tensioners is synonymous with achieving consistent wire tension that contributes to the efficiency, reliability, and performance of electric motors. The precise and uniform winding of motor coils, facilitated by the use of electrical tensioners, is essential for producing motors with the exact electrical characteristics and performance capabilities required for diverse industrial and commercial applications.

By leveraging the advanced control and precision capabilities of electrical tensioners, motor manufacturers can elevate the quality and performance of their products, ensuring the delivery of electric motors that meet the demanding standards of efficiency, reliability, and longevity in various operational environments.

Speaker Manufacturing

Applications in speaker manufacturing are characterized by the critical need for accurate tension control to produce high-quality speaker coils with precise impedance characteristics. In this context, electrical tensioners play a central role in ensuring the uniform winding of speaker coils, thereby contributing to the production of speakers with exceptional audio quality, tonal accuracy, and consistent performance across a range of sound frequencies.

By embracing the precision-driven solutions offered by electrical tensioners, speaker manufacturers can achieve a new standard of audio quality and performance, delivering speakers that meet the discerning requirements of audiophiles, sound engineers, and discerning consumers in the global market for high-fidelity audio equipment.

Each of these industry-specific applications underscores the profound impact of electrical tensioners on the quality, efficiency, and performance of the winding process, validating the strategic significance of incorporating these advanced solutions into the production lines of diverse manufacturing sectors.

Contact Itasca Automation Systems today to learn more about our Electric Tensioners.

Electrical tensioners play a crucial role in ensuring the quality and efficiency of coil winding processes. With various types available, such as mechanical, electronic, and magnetic tensioners, manufacturers can choose the best option for their specific winding needs. These tensioners provide precise tension control, adaptability to different wire specifications, reduced maintenance, and increased productivity. They are widely used in industries such as transformer manufacturing, motor production, and speaker manufacturing. As a reliable supplier of electrical tensioners, Itasca Automation Systems offers a range of high-performing options equipped with EMP Brake technology for superior performance and longevity.