2025 Top 5 Used Coil Winding Machines You Need for Your Business

As the manufacturing landscape evolves, the demand for efficient and reliable machinery continues to grow, particularly in sectors reliant on coil winding technology. According to a recent report by Market Research Future, the global coil winding machine market is projected to reach a value of $1.2 billion by 2025, driven largely by advancements in automation and an increase in the production of electric vehicles. In this competitive environment, understanding the best options for "used coil winding machines" becomes critical for businesses looking to optimize their operations and reduce costs.

Industry expert Dr. James Thornton, a noted figure in coil winding technology, emphasizes the importance of choosing high-quality equipment: “Investing in a used coil winding machine can significantly enhance production efficiency without the strain of new equipment costs.” As we approach 2025, identifying the top five used coil winding machines available on the market will not only help businesses make informed purchasing decisions but also ensure they stay ahead in this rapidly advancing industry. The subsequent analysis will delve into the features, advantages, and applications of these essential machines, providing a comprehensive guide for manufacturers seeking to elevate their production capabilities.

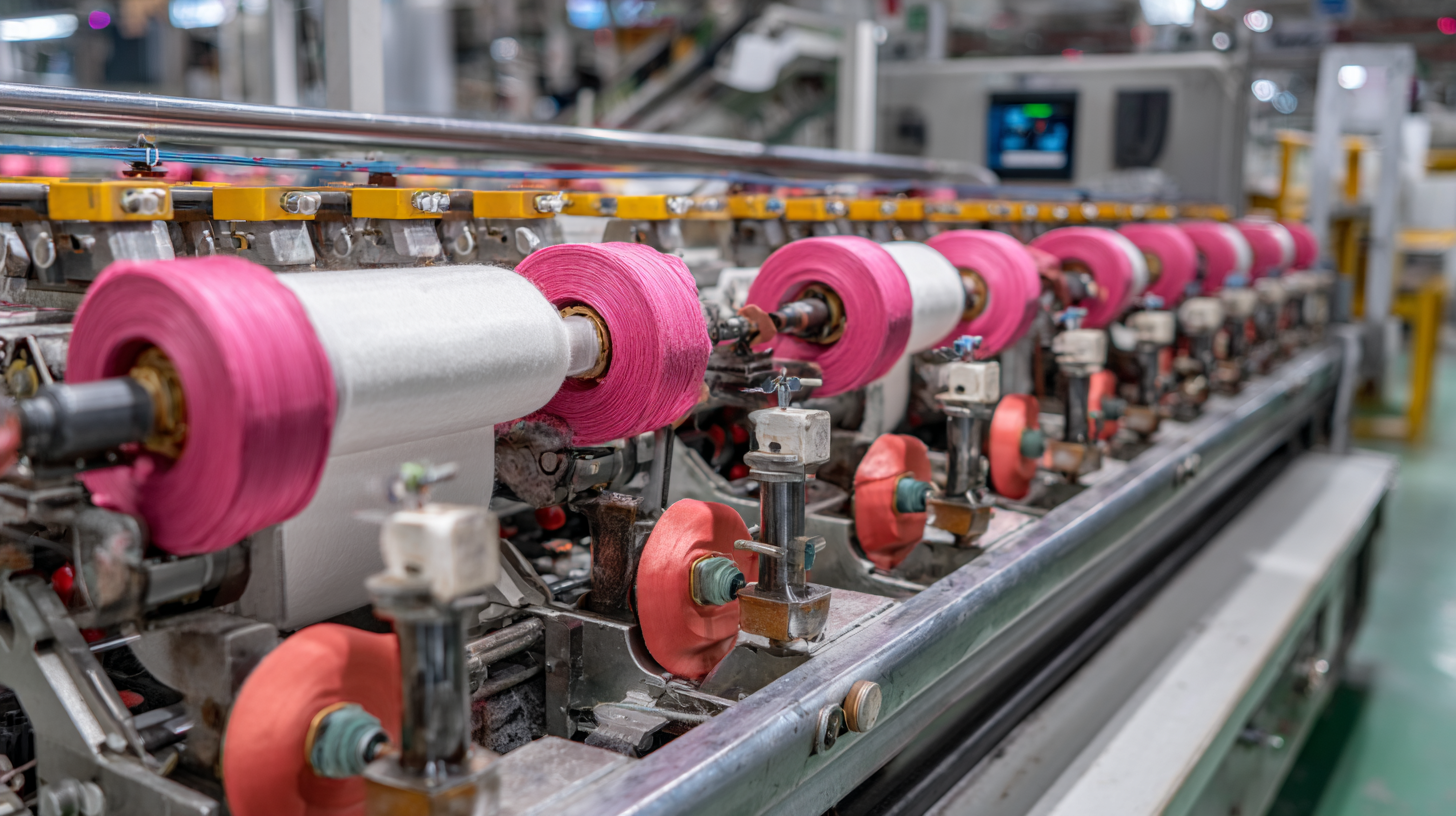

Essential Features to Look for in Coil Winding Machines for 2025

When selecting coil winding machines for 2025, it's crucial to focus on essential features that enhance productivity and precision. In the competitive landscape of manufacturing, machines equipped with advanced automation capabilities can significantly reduce labor costs and minimize human error.

According to a report by MarketsandMarkets, the global coil winding machine market is projected to reach $2.1 billion by 2025, driven by the increasing demand for electrical components in various industries. This underscores the necessity for businesses to invest in technology that keeps pace with industry advancements.

Another key feature to consider is the machine’s adaptability to different materials and winding techniques. As the demand for customized solutions grows, coil winding machines that can handle a variety of wire types and offer programmable settings will be invaluable. Tips for choosing the right machine include assessing the maximum coil diameter and weight it can accommodate, as these specifications directly affect your production capabilities.

Furthermore, energy efficiency is a growing trend in manufacturing. Machines designed with energy-saving features not only lower operational costs but also align with sustainability goals. A study by Grand View Research highlights that energy-efficient machines could save up to 30% in operational costs over their lifespan. Investing in such technology not only enhances your competitive edge but also contributes to a more sustainable business model.

Comparative Analysis: Top 5 Used Coil Winding Machines in the Market

The coil winding machine market is experiencing significant growth, driven by advancements in automation and the rising demand for precision in manufacturing. According to industry reports, the global coil winding machine market is projected to expand at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2034. This growth is attributed to the increasing need for efficient and high-quality production processes across various sectors, including electronics, automotive, and renewable energy.

In a comparative analysis of the top used coil winding machines available in the market, certain models stand out for their innovative features and reliability. These machines are equipped with state-of-the-art technology that enhances operational efficiency, thereby reducing downtime and maintenance costs. Furthermore, the integration of smart automation capabilities allows businesses to achieve higher precision and consistency in their winding processes, which is essential for meeting quality standards and customer expectations. With the expected market growth, investing in these top-used coil winding machines could prove beneficial for businesses aiming to enhance productivity and remain competitive in the evolving landscape.

2025 Top 5 Used Coil Winding Machines You Need for Your Business - Comparative Analysis

| Model | Max Coil Diameter (mm) | Winding Speed (RPM) | Number of Spools | Price Range ($) |

|---|---|---|---|---|

| Model A | 250 | 800 | 4 | 5000 - 7000 |

| Model B | 300 | 600 | 6 | 4500 - 6500 |

| Model C | 280 | 700 | 5 | 6000 - 8000 |

| Model D | 320 | 900 | 8 | 7000 - 9000 |

| Model E | 220 | 750 | 3 | 4000 - 6000 |

Cost-Effectiveness: How Used Machines Can Boost Your Profit Margins

In the competitive landscape of manufacturing, the cost-effectiveness of using used coil winding machines can significantly enhance your business’s profit margins. According to a recent report by IBISWorld, the market for used machinery in the manufacturing sector has been growing at an annual rate of 5.2%, highlighting the increasing reliance on previously-owned equipment. This trend is particularly relevant for businesses looking to invest in coil winding technology without facing the steep depreciation costs associated with new models.

Utilizing used coil winding machines not only lowers initial investment but can also lead to reduced operational costs. A study by the Machinery Industry Association revealed that companies can save between 20% to 40% on machinery costs by opting for well-maintained used equipment. Moreover, the reliability of modern used machines, equipped with advanced technology, ensures that companies do not have to compromise on quality or efficiency. By strategically incorporating these cost-effective solutions, businesses can allocate savings towards other crucial areas, such as product development and marketing, ultimately boosting their profitability in a crowded market.

2025 Top 5 Used Coil Winding Machines - Cost-Effectiveness Analysis

This chart displays the cost-effectiveness index of the top 5 used coil winding machines in 2025. Higher scores indicate better cost-effectiveness, which can significantly enhance profit margins for businesses using these machines.

Maintenance Tips for Prolonging the Life of Your Coil Winding Equipment

Proper maintenance of coil winding equipment is essential to ensure its longevity and optimal performance. Just as taking care of your headphones can extend their lifespan, using similar principles for coil winding machines can lead to significant improvements in durability and efficiency. Regularly cleaning the machinery, ensuring that all parts are free from dust and debris, can help prevent wear and tear. Additionally, inspecting for any loose components and tightening them as needed will greatly reduce the likelihood of malfunction during operations.

Moreover, it’s crucial to adhere to the manufacturer’s guidelines regarding lubrication and replacement of worn parts. Using high-quality lubricants can minimize friction between moving parts, while timely replacements of consumable items can prevent unexpected downtimes. Keep an organized maintenance schedule to monitor performance and allow for proactive interventions. By implementing these maintenance tips, businesses can maximize the lifespan of their coil winding machines, ensuring they deliver consistent quality in production for years to come.

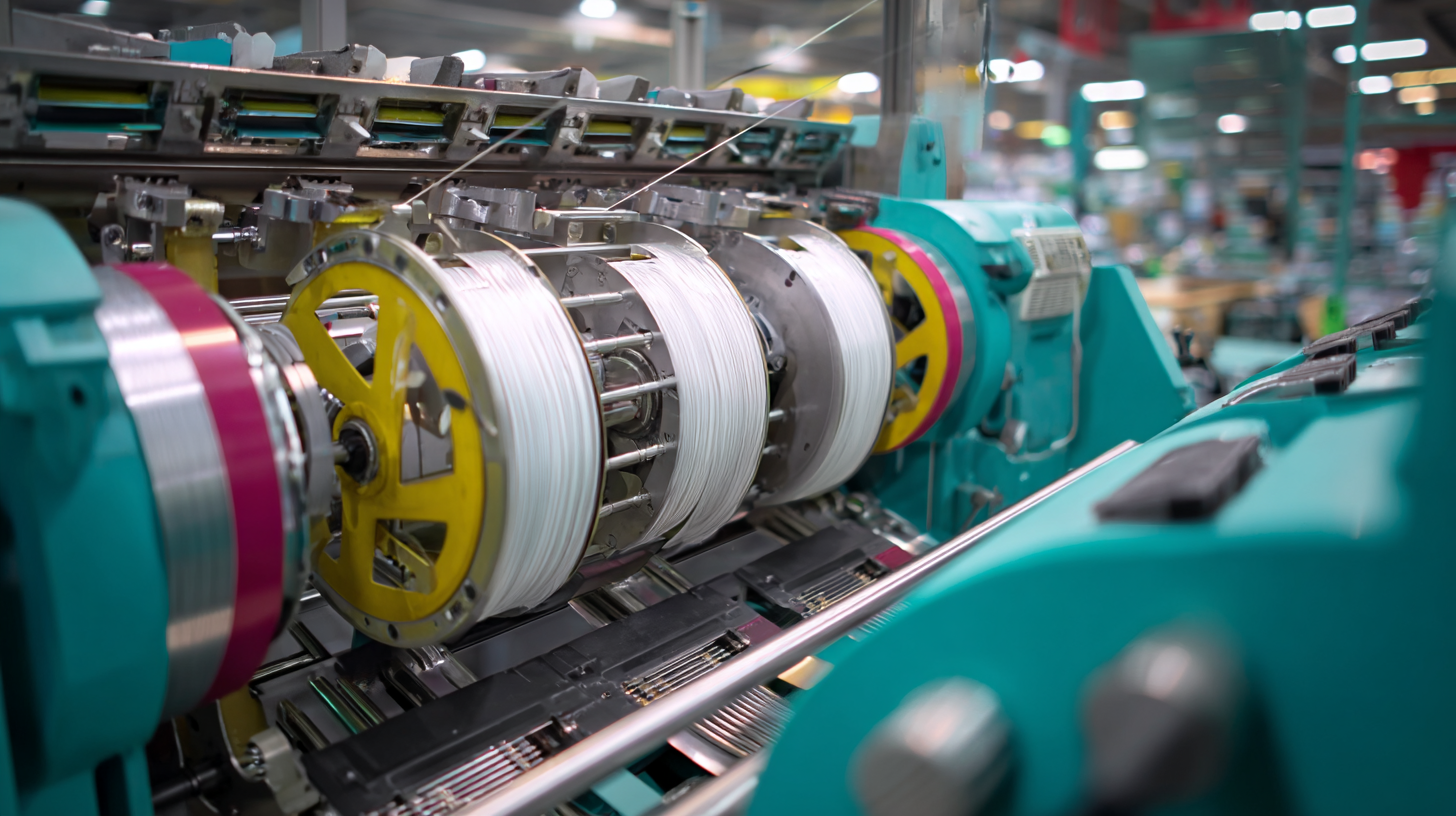

Future Trends in Coil Winding Technology to Watch in 2025

As we look toward 2025, the coil winding technology sector is set to undergo profound transformations driven by advancements in automation, machine intelligence, and energy efficiency. According to a report by MarketsandMarkets, the global market for coil winding machines is expected to grow from $1.2 billion in 2020 to over $1.8 billion by 2025, marking a CAGR of 8.5%. This growth highlights the increasing demand for precision and efficiency in manufacturing processes, particularly in industries such as automotive, electronics, and renewable energies.

One of the key trends shaping the future of coil winding technology is the integration of Industry 4.0 principles, which emphasize connectivity and data analytics. Smart coil winding machines equipped with IoT capabilities are becoming commonplace, allowing manufacturers to gather real-time data and optimize production processes. Another emerging trend is the emphasis on energy-efficient machines that reduce waste and lower operating costs, aligning with global sustainability goals. A study from ResearchAndMarkets indicates that energy-efficient coil winding solutions could reduce operational energy consumption by as much as 30%, a significant factor for businesses looking to improve their bottom line while adhering to eco-friendly practices.