Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

As the demand for precision and efficiency in manufacturing continues to rise, the importance of advanced machinery cannot be overstated. The best coil winding machine technology stands at the forefront of this evolution, enabling manufacturers to enhance productivity while ensuring the highest quality standards. According to a recent market research report by Grand View Research, the global coil winding machine market is projected to reach $2.5 billion by 2025, growing at a CAGR of 5.2%. This growth is driven by innovations in automation, improved winding techniques, and the integration of smart technology into manufacturing processes.

Companies that invest in the best coil winding machines can achieve significant cost savings and optimized production capabilities, positioning themselves competitively in the rapidly changing landscape of the industry. By focusing on these innovative solutions, manufacturers can not only meet current demands but also anticipate future market trends.

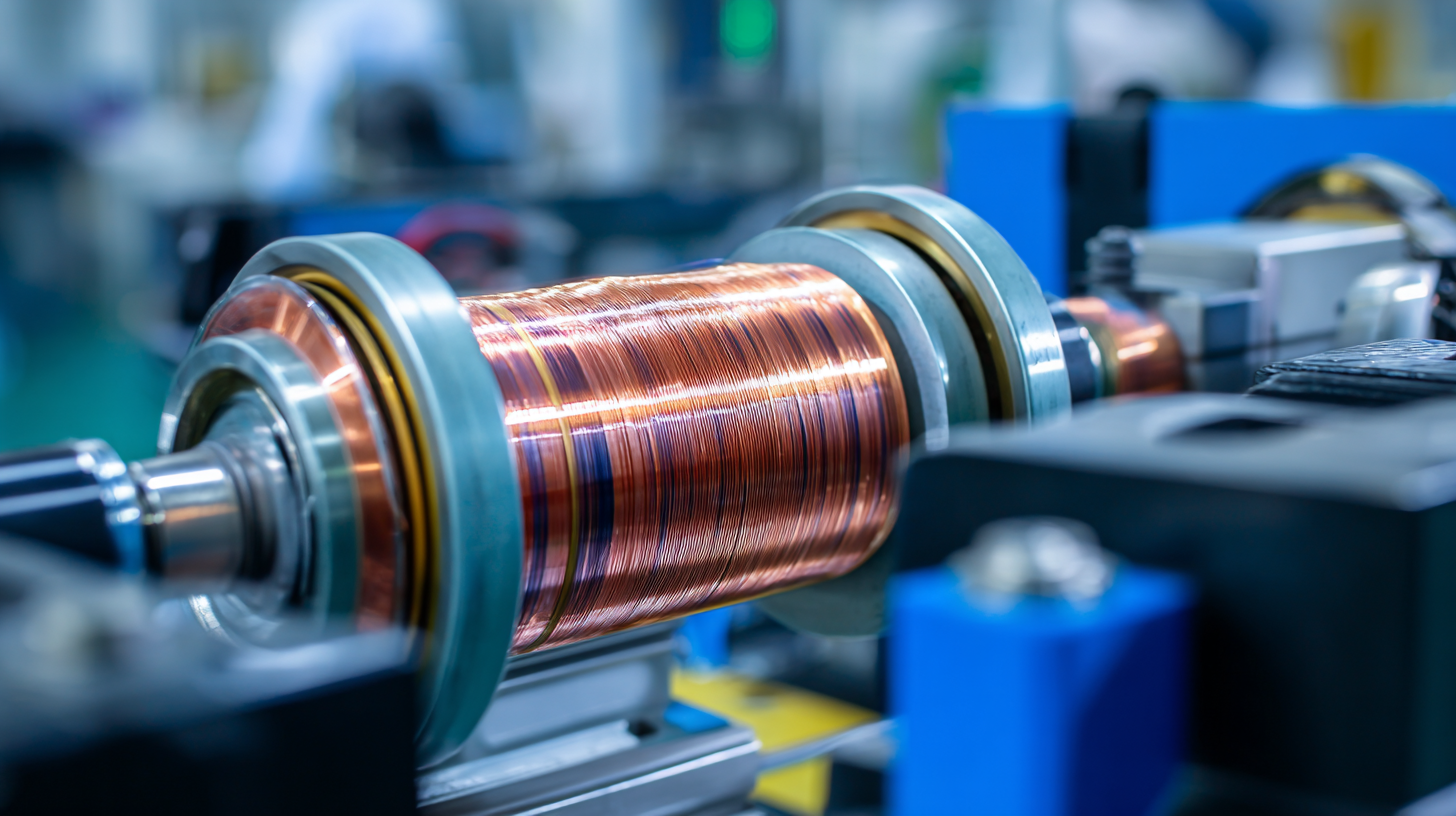

Understanding the Basics: What is Coil Winding and Its Importance in Production

Coil winding is a crucial process in the manufacturing of electrical components, involving the precise arrangement of wire in a coil form to create inductors, transformers, and motors. This technique is essential for energy efficiency and performance in various applications, ranging from consumer electronics to industrial machinery. According to a market report from MarketsandMarkets, the global coil winding machine market is expected to reach $1.2 billion by 2026, highlighting its significance in modern production.

The advancements in coil winding machine technology have led to higher productivity and lower operational costs. Modern machines feature automated settings that allow for quick adjustments to wire tension and winding patterns, which can drastically reduce setup times by up to 30% (TechNavio). In today's competitive market, manufacturers must adopt efficient coil winding practices to maintain an edge.

Tips: When integrating new coil winding technology, consider investing in machines with advanced software for real-time monitoring and troubleshooting. Regular training for operators can also enhance productivity and product quality—ensuring that your production line remains optimized for efficiency and innovation.

Key Innovations in Coil Winding Machine Technology for Enhanced Efficiency

The advancements in coil winding machine technology have significantly transformed manufacturing processes, pushing efficiency to new heights. One key innovation is the integration of smart automation systems. These systems utilize AI and machine learning algorithms to optimize the winding process, reducing setup times and minimizing waste. With real-time monitoring capabilities, manufacturers can make quick adjustments, ensuring that production runs smoothly and meets high-quality standards.

Tip: To enhance the effectiveness of your production line, consider investing in machines with built-in diagnostic tools that alert operators to potential issues before they escalate, saving both time and resources.

Another noteworthy development is the introduction of advanced materials in coil winding machinery. From lighter components to more durable structural elements, these innovations not only improve the reliability of the machines but also contribute to better energy efficiency. This means reduced power consumption during operation, leading to a lower carbon footprint and cost savings over time.

Tip: Regularly maintain your coil winding equipment to ensure that state-of-the-art materials and technologies continue to perform at optimal levels, further extending the life of your investment.

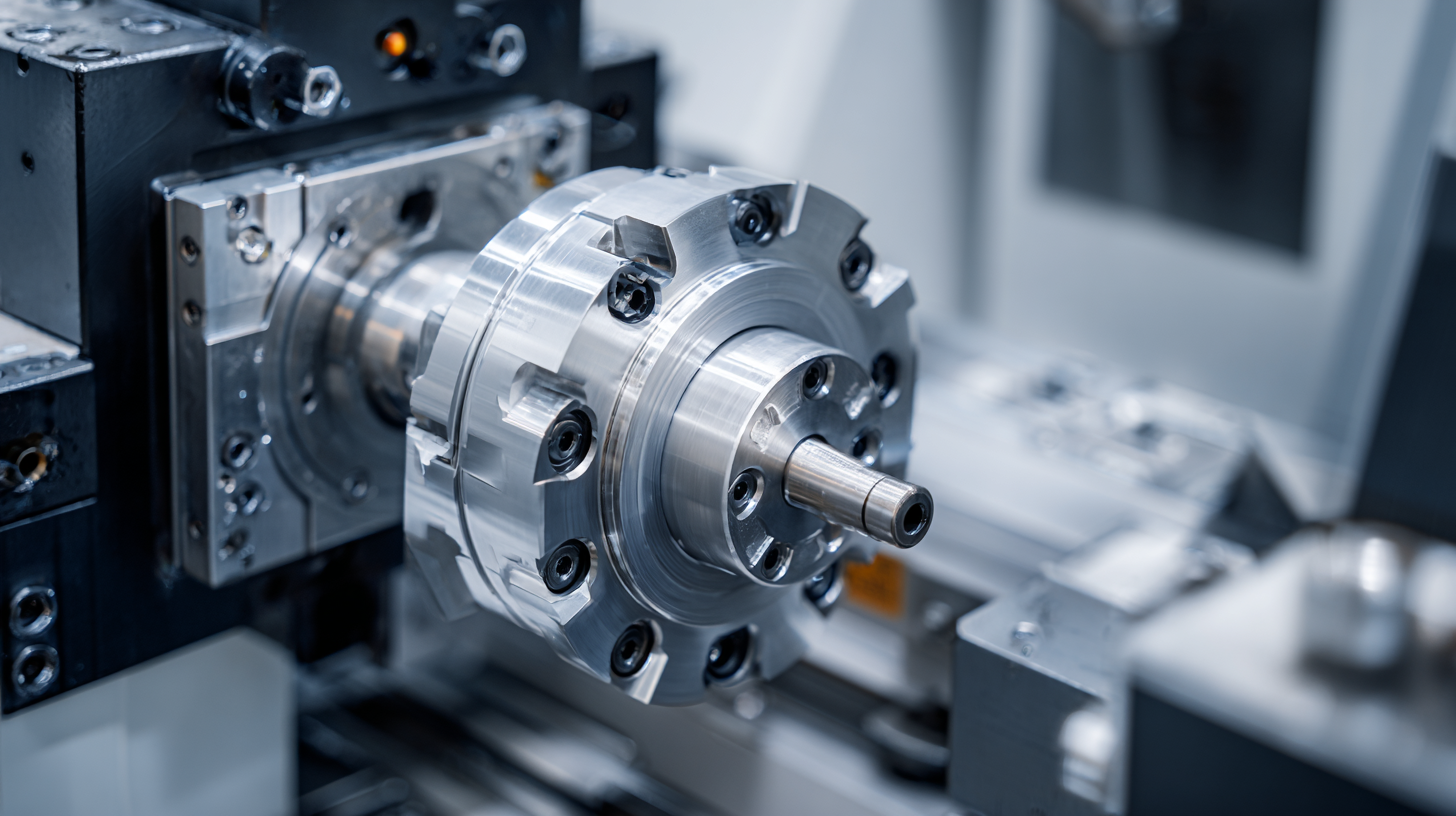

Analyzing Performance Metrics: Production Speed and Quality Improvements

The ongoing advancements in coil winding machine technology have significantly improved performance metrics, especially concerning production speed and quality. With the integration of smart automation and precision engineering, modern machines can achieve faster winding cycles without compromising the integrity of the coils. These innovations, such as automatic tension control and programmable settings, allow for quicker adjustments and reduced downtime, leading to enhanced overall productivity on the manufacturing floor.

Moreover, the emphasis on quality improvements has led to the development of sophisticated monitoring systems that provide real-time feedback during the winding process. These systems employ advanced sensors and machine learning algorithms to detect anomalies, ensuring that each coil meets stringent quality standards. By minimizing defects and optimizing wind patterns, manufacturers can significantly reduce waste and enhance the reliability of their products. The combination of increased speed and superior quality positions companies to not only meet but exceed customer expectations in an increasingly competitive market.

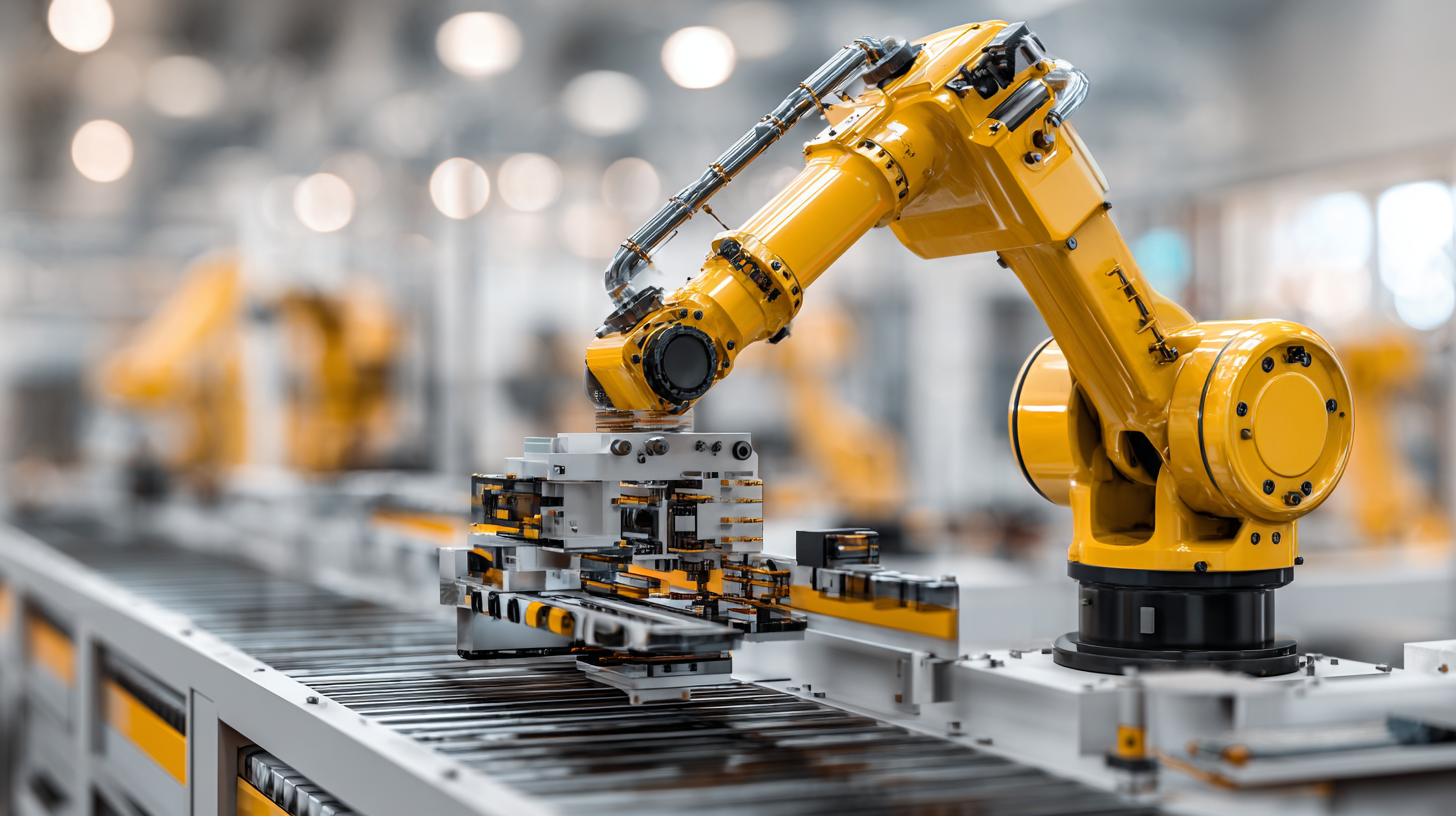

The Role of Automation in Modern Coil Winding Machines

The evolution of coil winding machines has been significantly influenced by advancements in automation technology. Modern coil winding machines are increasingly integrated with automated systems that streamline the production process, reducing human error and enhancing efficiency. With the use of sophisticated sensors and programmable logic controllers (PLCs), these machines can adjust their operations in real-time, ensuring precise winding configurations and minimizing waste. Automation not only accelerates the winding process but also allows for more intricate designs, catering to the specific needs of various industries.

Moreover, the role of automation extends beyond mere speed enhancements. It facilitates enhanced data collection and analysis, empowering manufacturers to monitor machine performance and production metrics closely. Through the adoption of smart technologies, operators can receive alerts about potential issues before they escalate, allowing for timely maintenance and uninterrupted production flow. As a result, companies can achieve higher levels of productivity and profitability, positioning themselves competitively in the market while meeting the growing demands of coil manufacturers for efficiency and precision.

Future Trends: Integrating Smart Technology and IoT in Coil Winding Manufacturing

The integration of smart technology and the Internet of Things (IoT) in coil winding manufacturing is transforming the sector, leading to enhanced efficiency and productivity. Recent advancements showcase how IoT facilitates real-time data collection and analysis, allowing manufacturers to monitor machinery performance and predict maintenance needs proactively. For instance, with the rise of Industry 4.0, manufacturers are increasingly adopting cloud-based data platforms to streamline operations, as highlighted by recent discussions in industrial technology forums.

Reports indicate that the global demand for advanced coil winding machines is on the rise, driven by the proliferation of electric vehicles and renewable energy solutions, which are reliant on efficient winding processes. Companies are turning to smart technology to optimize their production lines, resulting in a significant reduction in downtime and operational costs. According to market analyses, the integration of smart sensors in the winding process can enhance quality control and reduce material waste by over 20%.

Tip: When considering upgrades to your coil winding machines, explore options that offer integrated IoT solutions for real-time performance monitoring to maximize efficiency.

Tip: Stay informed about the latest trends in coil winding technology by attending industry exhibitions, which often showcase innovative developments and networking opportunities with key manufacturers.