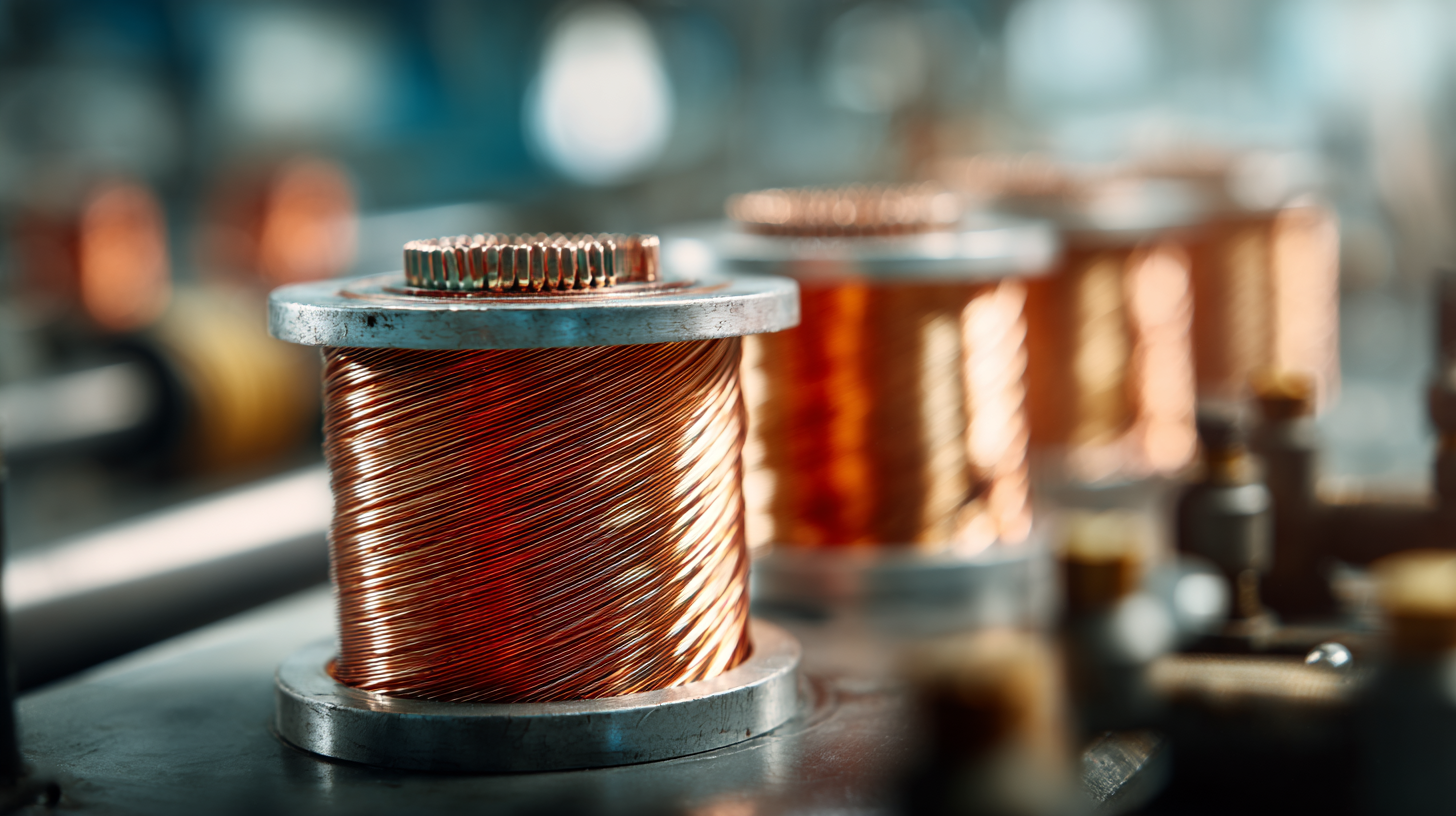

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

In the rapidly evolving landscape of manufacturing, the importance of selecting the right motor coil winding machine cannot be overstated. As the global market for electric motors is projected to reach approximately $200 billion by 2025, driven by advancements in electric vehicles and renewable energy technologies, the demand for efficient and precise coil winding solutions is at an all-time high. According to a recent report by MarketsandMarkets, the market for motor winding machinery is expected to witness a CAGR of 6.5% over the next five years, highlighting the critical role that these machines play in enhancing production efficiency and product quality.

Understanding the specific needs of your operation is essential when choosing a motor coil winding machine. Factors such as machine capability, automation level, and winding precision directly influence the performance of the final product.

With an increase in complex winding patterns and the need for higher output, manufacturers must navigate through various options available in the market. Additionally, industry leaders emphasize that investing in the latest technology not only improves output quality but also significantly reduces waste, thereby aligning with sustainability goals that are becoming increasingly important in today's manufacturing processes.

As we approach 2025, making an informed choice about motor coil winding machines will undoubtedly serve as a stepping stone towards operational excellence and competitive advantage.

Understanding Your Motor Coil Winding Requirements for 2025

When selecting the best motor coil winding machine for your needs in 2025, it is crucial to understand your specific winding requirements. Consider the type of motors you will be winding and their respective sizes, shapes, and complexities. Different applications may demand unique specifications, such as winding speed, precision, and wire gauge compatibility. Therefore, a clear analysis of the motor types you intend to work with will guide you in choosing a machine that meets those demands efficiently.

Additionally, as technology continues to evolve, it is important to look for machines that incorporate the latest innovations in coil winding technology. Features such as automated processes, user-friendly interfaces, and maintenance requirements should be evaluated. Manufacturers may offer advanced systems that enhance efficiency and ensure higher quality outputs. By aligning your purchasing criteria with these technological advancements, you can select a motor coil winding machine that not only meets today’s standards but also prepares you for future developments in the industry.

Key Features to Consider in Modern Coil Winding Machines

When selecting the best motor coil winding machine in 2025, it’s essential to focus on key features that will enhance productivity and ensure precision. One critical feature to consider is the machine's winding speed. According to a market analysis by Smith Market Research, modern coil winding machines can reach speeds of up to 1,200 RPM, significantly reducing production time without compromising quality. Faster winding capabilities not only increase output but also allow for the production of complex designs that meet the evolving demands of industries such as automotive and electronics.

Another important characteristic is the machine's programmability and user interface. Advanced models are equipped with intuitive touchscreens and customizable programs, allowing operators to adjust parameters easily for different coil types. A study conducted by TechResearch Insights estimates that over 65% of manufacturers prioritize ease of use and flexibility in their coil winding operations. Additionally, automated features like tension control and end-of-wire detection are increasingly common, which enhance precision and reduce material waste. By prioritizing these modern features, businesses can ensure they invest in technology that meets current and future production needs effectively.

Evaluating the Technology Trends Impacting Motor Coil Winding

When selecting the best motor coil winding machine for your needs in 2025, it is vital to consider the evolving technology trends that are shaping the industry. As electric motor technology advances, the demand for efficient and precise coil winding machines increases. Innovations such as advanced motor circuit analysis technology are making it easier to assess and maintain motors, thereby prolonging their lifespan and enhancing performance. The integration of enhanced thermal management in electric motors is another crucial aspect, as it directly influences the material needed to create efficient magnetic fields.

**Tips for Choosing the Right Machine:**

1. Look for machines that incorporate the latest advancements in motor circuit analysis, as they can provide valuable insights into the operational efficiency and condition of your winding processes.

2. Consider machines with features that support thermal management, as this can significantly affect the performance of the motors produced, impacting overall productivity and quality.

Moreover, the introduction of novel technologies like dynamic power management software is revolutionizing how coils are controlled, offering more sophisticated and adaptive winding solutions. As AI and 3D printing continue to penetrate the industry, their potential to improve coil production processes should not be underestimated.

Motor Coil Winding Machine Technology Trends in 2025

Budgeting for Your Coil Winding Machine: Costs vs. Benefits

When budgeting for a coil winding machine, it's essential to weigh the initial costs against the long-term benefits. According to a report by Grand View Research, the global market for coil winding machines is expected to grow at a CAGR of 5.2% from 2023 to 2030, highlighting the increasing demand for high-efficiency manufacturing tools. Investing in a high-quality machine not only optimizes production speed but also reduces waste and improves the overall quality of the final product. For instance, a premium motor coil winding machine may involve a higher upfront investment, but the enhanced precision and durability can lead to significant cost savings over time.

Moreover, cheaper alternatives often come with hidden costs in terms of maintenance and operation. A study by MarketsandMarkets suggests that up to 30% of a machine's total cost of ownership is attributed to maintenance and repairs. For businesses planning to scale, investing in a reliable machine can lead to reduced downtime and increased production capacity, which ultimately contributes to a healthier bottom line. Balancing the initial purchase price with the expected operational efficiency and longevity is crucial in making an informed decision when choosing the best coil winding machine for your needs.

Assessing Supplier Reputation and Support for Optimal Performance

When selecting a motor coil winding machine, evaluating the reputation and support of suppliers is critical for ensuring optimal performance. A reliable supplier should not only provide high-quality machines but also offer robust technical support and customer service. Companies should consider utilizing supplier identification and evaluation services that streamline the process of selecting suitable partners. These services can guide businesses through the complexities of supplier selection by assessing capability, reliability, and after-sales support based on comprehensive criteria.

Additionally, gathering feedback from other users can significantly inform decision-making. Reviews and surveys can provide insights into suppliers' performance, including quality and responsiveness. As demonstrated in various industry assessments, knowing your vendor's standing within the market helps mitigate risks, lower costs, and maximize revenue potential. In an era of increasing competition and technological changes, investing time in supplier evaluation can yield substantial long-term benefits for businesses seeking to enhance their manufacturing capabilities with the best motor coil winding machines.